What You Need To Know About CNC Machine Tooling

As the technology of 3D printing continues to evolve, so does the way in which products are created. One such technology that has seen a resurgence in recent years is CNC machine tooling. In this article, we'll be exploring what CNC machine tooling is, its benefits, and some of the key considerations you should take into account when purchasing it.

What is CNC machine tooling?

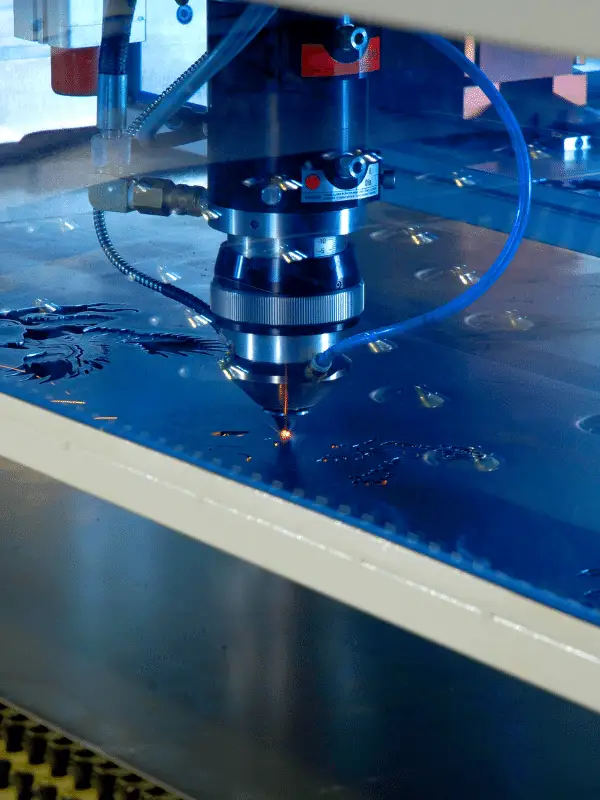

CNC machine tooling is a manufacturing process that uses computer-controlled cutting tools to create parts from a solid block of material. It’s the most advanced way to produce parts and is becoming more popular as companies look for ways to reduce waste, speed up production, and improve quality.

How does CNC machine tooling work?

To start, the computer controls the movement of the cutting tool, which cuts the material. The cutting tool is movable so that it can move along the desired path. This requires a precise alignment between the cutting tool and the block of material. The block of material is typically held in place by a clamp or other device.

There are several types of CNC machine tooling: manual, semi-automatic, and automatic. Manual CNC machine tooling involves a person operating the machine; semi-automatic CNC machine tooling allows for some automation (a user must manually input the information needed to control the machine), while automatic CNC machine tooling takes care of all the required inputs for cutting (speed, feed rate, etc.).

There are many benefits to using CNC machine tooling over other methods:\

Types of CNC machine tooling

Choosing the right type of CNC machine tooling for your project can be a daunting task. There are a variety of types of CNC machine tooling available, each with its own advantages and disadvantages. Here is a brief overview of the most common types of CNC machine tooling.

Metal Cutting Machinery: Metal cutting machinery is the most common type of CNC machine tooling. It typically uses a rotary motion to cut metal objects. Metal cutting machines come in two main varieties: manual and automatic. Manual machines require a skilled operator to operate them, while automatic machines are operated by computer. Automatic machines are more versatile, but they can also be more expensive.

Woodworking Machinery: Woodworking machinery uses a variety of cutting and shaping motions to create items out of wood. The most common type of woodworking machinery is a band saw. Band saws use a circular saw blade to cut through sheets of wood. They are relatively easy to operate, but they can be slow and require extensive training to use effectively. Other types of woodworking machinery include lathes, routers, miter saws and planers. Lathes and routers use rotary or linear motions to shape pieces

Advantages and Disadvantages of CNC machine tooling

CNC machine tooling is one of the most versatile and efficient ways to manufacture products. It’s a high-speed, computer-controlled process that uses cutting tools to create parts from metal, plastic or other materials. There are several benefits and disadvantages of using CNC machine tooling. Here are four key points to consider:

Advantages of CNC Machine Tooling

-Very precise and accurate manufacturing: CNC machine tooling offers extremely precise and accurate manufacturing, which is why it’s used in a wide variety of industries. Parts can be created with incredible accuracy and precision, which is great for products that need to meet very specific specifications.

-High speed and productivity: CNC machines are incredibly fast and productive, meaning you can create multiple parts simultaneously without having to wait long periods of time between each step. This speeds up the manufacturing process considerably and allows you to get your products to market faster.

-No need for manual labor: Aside from being incredibly fast and efficient, CNC machine tooling also eliminates the need for any manual labor. This means you can focus on other tasks while your machine does the actual work – making it an ideal choice if you have

Cost of CNC machine tooling

When you are considering the purchase of a CNC machine, it is important to understand the cost of machine tooling. There are a few factors involved in this price, such as the type of machine you are purchasing and the type of tooling you will need. Here are a few things to keep in mind:

-The more complex the machine, the more expensive the tooling will be. For example, a 3D printer requires specialized tooling that is not typically found on standard CNC machines.

-The type of tooling required will depend on the type of operation your CNC machine will be used for. For example, if you plan to use your CNC machine to create precise parts, you will need tooling that can cut precise angles and shapes. On the other hand, if you just want to create simple items like brackets or shelves, less sophisticated tools may be sufficient.

-Tooling prices can also change depending on the manufacturer and model. As such, it is important to do your research before making a purchase so that you know what is actually costs for the specific type of tooling you need.

Conclusion

CNC machine tooling is a versatile and essential manufacturing process that allows for the creation of intricate, precision parts. In this article, we have outlined the key benefits of using CNC machine tooling and provided a few tips on how to get started in the industry. If you are looking to invest in or expand your CNC machine tooling capabilities, be sure to read through our article carefully as it may contain all the information you need. Thanks for reading!https://machingchina.com/cnc-m....achining-polycarbona

喜欢

评论

分享