Entdecken Beiträge

Preventing Injection Moulding Defects: A Comprehensive Guide for Manufacturers

Injection moulding is a commonly process for manufacturing for production of plastic parts in large quantities. However, different injection moulding defects may occur during the production, which can affect the quality and performance of the final product. Understanding such plastic defects better for prevention is important for manufacturers focusing to produce best quality components.

1. Flow Lines

Flow lines are patterns that are quickly visible on the surface of the molded parts. They usually occur when the molten plastic flows at different speeds inside the mold, which leads to solidifying at different times. The common causes are low injection speed or pressure as well as difference in the wall thickness.

Prevention:

Speed up the injection process, including pressure to make sure the uniform flow.

There should be consistent wall thickness or gradual transitions between the sections with different thicknesses.

Position gates in sections with thinner walls to generate even flow.

2. Sink Marks

The sink marks injection moulding are the depressions or simples that form on the surface of the molded parts. They occur in the thicker sections. They form in the inner portions of the part when it is cooled down at different rates that the outer surfaces.

Prevention:

Give enough cooling time within the mould to make sure of uniform curling.

Decrease the wall thickness in thicker areas to allow equal cooling time.

Enhance the holding pressure during moulding to compensate for the shrinking of the material.

3. Surface Delamination

Delamination is nothing but the thin layers on the part’s surface that easily peel away that resembles a coating. This defect because of the presence contaminants in the material that fail to form a strong bond with the plastic or excessive use of mold release agents.

Prevention:

Make sure to pre-dry the plastic materials before the moulding process to avoid moisture.

Reduce the use of mould release agents to optimize the ejection mechanism.

Increase the temperatures in the moulding process to promote improved bonding of materials.

4. Weld Lines

These are also known as the knit lines; these appear where the two flow fronts of molten plastic are present in the mold. These lines can make the structural integrity very weak and are often found around the holes or obstructions present in the mold. To learn more about preventing weld lines and to achieve high-quality parts, check our Guide to Injection Moulding process

Prevention:

Allow to increase the temperature of the mould as well as the molten plastic to make sure of the better fusion.

Align the injection speed to avoid premature cooling before flow fronts begin to merge.

Redesign the mould to position the gates again and reduce the weld lines.

5. Short Shots

A short shot is seen when the mold cavity is not completely filled up to the mark, which results inssure and speed to fill the mold completely.

Make sure that there is a sufficient supply the incomplete parts. This problem can result from the insufficient material, low injection pressure, or improper venting.

Prevention:

Implement sufficient injection prey of material for each shot.

Mend the venting in the mould to escape the air during the injection process.

6. Warping

This is the distortion or bending of the end product after ejection from the mold, which often occur due to uneven cooling or maybe because of internal stresses.

Prevention:

Design the mould in a way that has a uniform wall thickness, reducing internal stresses.

Balance the cooling rates and make sure temperature distribution occurs within the mould even.

Choose the material that has apt shrinkage characteristics for the desired design.

7. Burn Marks

Burn marks are seen when there is black or brown discoloration on the surface of the product, usually caused by trapped air or degraded resin.

Prevention:

Increase the mould venting to allow the trapped air to escape.

Drop the injection speed to avoid compression of the air and overheating.

Make sure proper care of equipment is taken to prevent resin degradation.

Conclusion

That’s it! Understanding these common injection molding defects and quickly implementing the appropriate preventative measures, manufacturers can boost their quality of the product and reduce the rework as well as its cost. Investing in the advanced plastic injection moulding machine can work well to streamline the production processes and minimize defects. If you’re ready to take your manufacturing to the next level connect with our experts today.

Website Link : https://www.shibauramachine.co.in/

Preventing Injection Moulding Defects: A Comprehensive Guide for Manufacturers

Injection moulding is a commonly process for manufacturing for production of plastic parts in large quantities. However, different injection moulding defects may occur during the production, which can affect the quality and performance of the final product. Understanding such plastic defects better for prevention is important for manufacturers focusing to produce best quality components.

1. Flow Lines

Flow lines are patterns that are quickly visible on the surface of the molded parts. They usually occur when the molten plastic flows at different speeds inside the mold, which leads to solidifying at different times. The common causes are low injection speed or pressure as well as difference in the wall thickness.

Prevention:

Speed up the injection process, including pressure to make sure the uniform flow.

There should be consistent wall thickness or gradual transitions between the sections with different thicknesses.

Position gates in sections with thinner walls to generate even flow.

2. Sink Marks

The sink marks injection moulding are the depressions or simples that form on the surface of the molded parts. They occur in the thicker sections. They form in the inner portions of the part when it is cooled down at different rates that the outer surfaces.

Prevention:

Give enough cooling time within the mould to make sure of uniform curling.

Decrease the wall thickness in thicker areas to allow equal cooling time.

Enhance the holding pressure during moulding to compensate for the shrinking of the material.

3. Surface Delamination

Delamination is nothing but the thin layers on the part’s surface that easily peel away that resembles a coating. This defect because of the presence contaminants in the material that fail to form a strong bond with the plastic or excessive use of mold release agents.

Prevention:

Make sure to pre-dry the plastic materials before the moulding process to avoid moisture.

Reduce the use of mould release agents to optimize the ejection mechanism.

Increase the temperatures in the moulding process to promote improved bonding of materials.

4. Weld Lines

These are also known as the knit lines; these appear where the two flow fronts of molten plastic are present in the mold. These lines can make the structural integrity very weak and are often found around the holes or obstructions present in the mold. To learn more about preventing weld lines and to achieve high-quality parts, check our Guide to Injection Moulding process

Prevention:

Allow to increase the temperature of the mould as well as the molten plastic to make sure of the better fusion.

Align the injection speed to avoid premature cooling before flow fronts begin to merge.

Redesign the mould to position the gates again and reduce the weld lines.

5. Short Shots

A short shot is seen when the mold cavity is not completely filled up to the mark, which results inssure and speed to fill the mold completely.

Make sure that there is a sufficient supply the incomplete parts. This problem can result from the insufficient material, low injection pressure, or improper venting.

Prevention:

Implement sufficient injection prey of material for each shot.

Mend the venting in the mould to escape the air during the injection process.

6. Warping

This is the distortion or bending of the end product after ejection from the mold, which often occur due to uneven cooling or maybe because of internal stresses.

Prevention:

Design the mould in a way that has a uniform wall thickness, reducing internal stresses.

Balance the cooling rates and make sure temperature distribution occurs within the mould even.

Choose the material that has apt shrinkage characteristics for the desired design.

7. Burn Marks

Burn marks are seen when there is black or brown discoloration on the surface of the product, usually caused by trapped air or degraded resin.

Prevention:

Increase the mould venting to allow the trapped air to escape.

Drop the injection speed to avoid compression of the air and overheating.

Make sure proper care of equipment is taken to prevent resin degradation.

Conclusion

That’s it! Understanding these common injection molding defects and quickly implementing the appropriate preventative measures, manufacturers can boost their quality of the product and reduce the rework as well as its cost. Investing in the advanced plastic injection moulding machine can work well to streamline the production processes and minimize defects. If you’re ready to take your manufacturing to the next level connect with our experts today.

Website Link : https://www.shibauramachine.co.in/

Homes for Sale Ontario

https://realestateramani.com/all-area-listings

Discover your dream home with Imraz Ramani Real Estate! Explore a wide range of modern, newly built homes for sale in Ontario’s most desirable neighborhoods. Whether you’re a first-time buyer or upgrading, we help you find the perfect property that matches your lifestyle and investment goals.

#homesforsaleontario

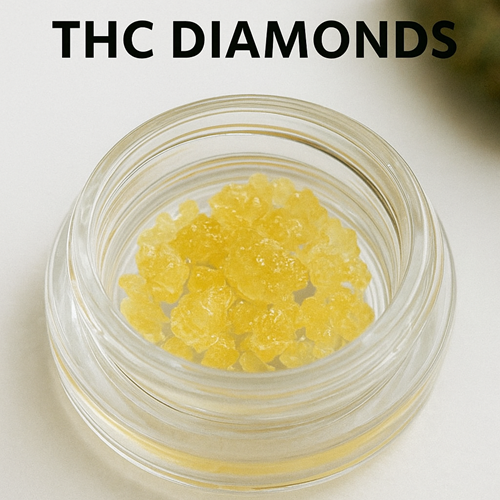

Buy Premium THC Diamonds in Canada | RightPuff London, ON

Buy premium THC diamonds from RightPuff in London, Ontario, Canada. Experience ultra-pure, high-potency cannabis concentrates with exceptional flavor and smooth effects. For more information, please read the blog here!

https://geniusvision.world/buy....-premium-thc-diamond

California Practice Permit Test | Mydrivepermit.com

Start your CA DMV Practice Test Course today at MyDrivePermit.com. Get ready for the California permit test with expert-designed practice questions and study guides.

About Company:-

Get your driving permit hassle-free with MyDrivePermit’s self-paced online course. Get essential knowledge and skills, including a certificate. Start worry-free today with our price match guarantee! (See FAQs for details). We take great pride in delighting thousands of happy customers.

Click Here For More Info:- https://mydrivepermit.com/ld-n....otification/welcome-

Social Media Profile Links:-

https://www.facebook.com/mydrivepermit

https://www.instagram.com/learnandpermits/